Basics of cobot automation

Driven by the increasing demand for post-collaborative robots from small and medium-sized enterprises, the cobot market is growing rapidly (annual growth rates of over 30%!).

But are collaborative robots also suitable for your processes? This article answers that question based on the 9 most important questions you should ask yourself before choosing a cobot.

What is a cobot?

By definition, a cobot (abbreviation for”Collaborative robot“) is a collaborative robot that developed specifically for human-robot collaboration.

What is the difference with conventional industrial robots?

The difference to classic robots is built-in sensors that enable cobots to safely share the work area with humans even without a safety fence.

Unexpected collisions, e.g. with a human, result in an immediate stop of the cobots. Injuries to employees caused by cobots are therefore ruled out.

Which EU-Norms are important for cobot applications?

In order to ensure occupational safety and obtain a CE declaration of conformity, the following standards are particularly relevant:

- ISO 10218-1: Guidelines for robot manufacturers

- ISO 10218-2: Requirements for the robot system (for integrators)

- ISO/TS 15066: Specifications for human-robot collaboration

The TS 15066 includes, among other things, guideline values for the maximum permitted speeds of cobots. Compliance with these and other relevant standards is mandatory under the Machinery Directive (MRL) 2006/42/EC, which applies to all manufacturers and suppliers of machinery within the EU.

The Fraunhofer IGCV guidelines explains this topic in detail.

What can a cobot do?

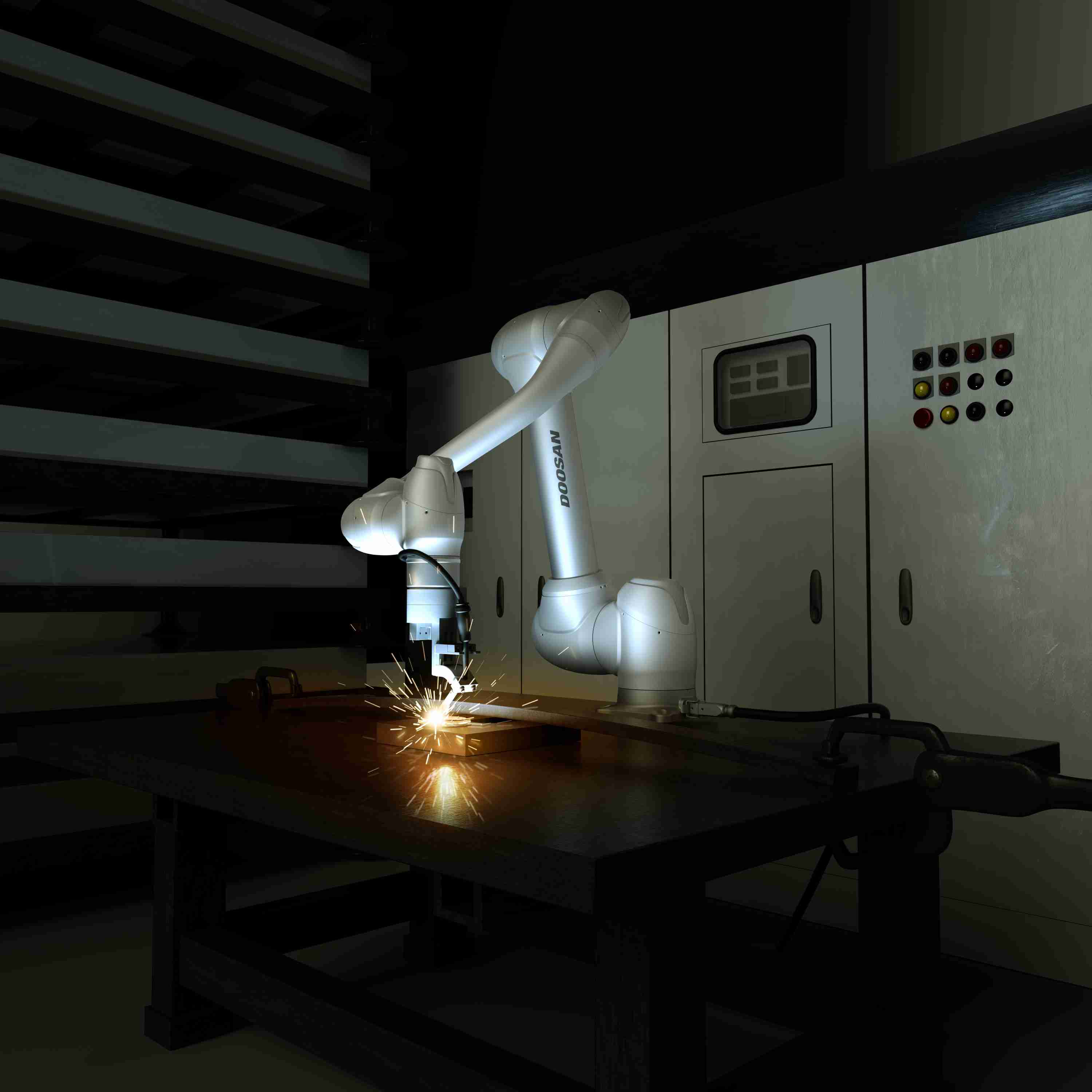

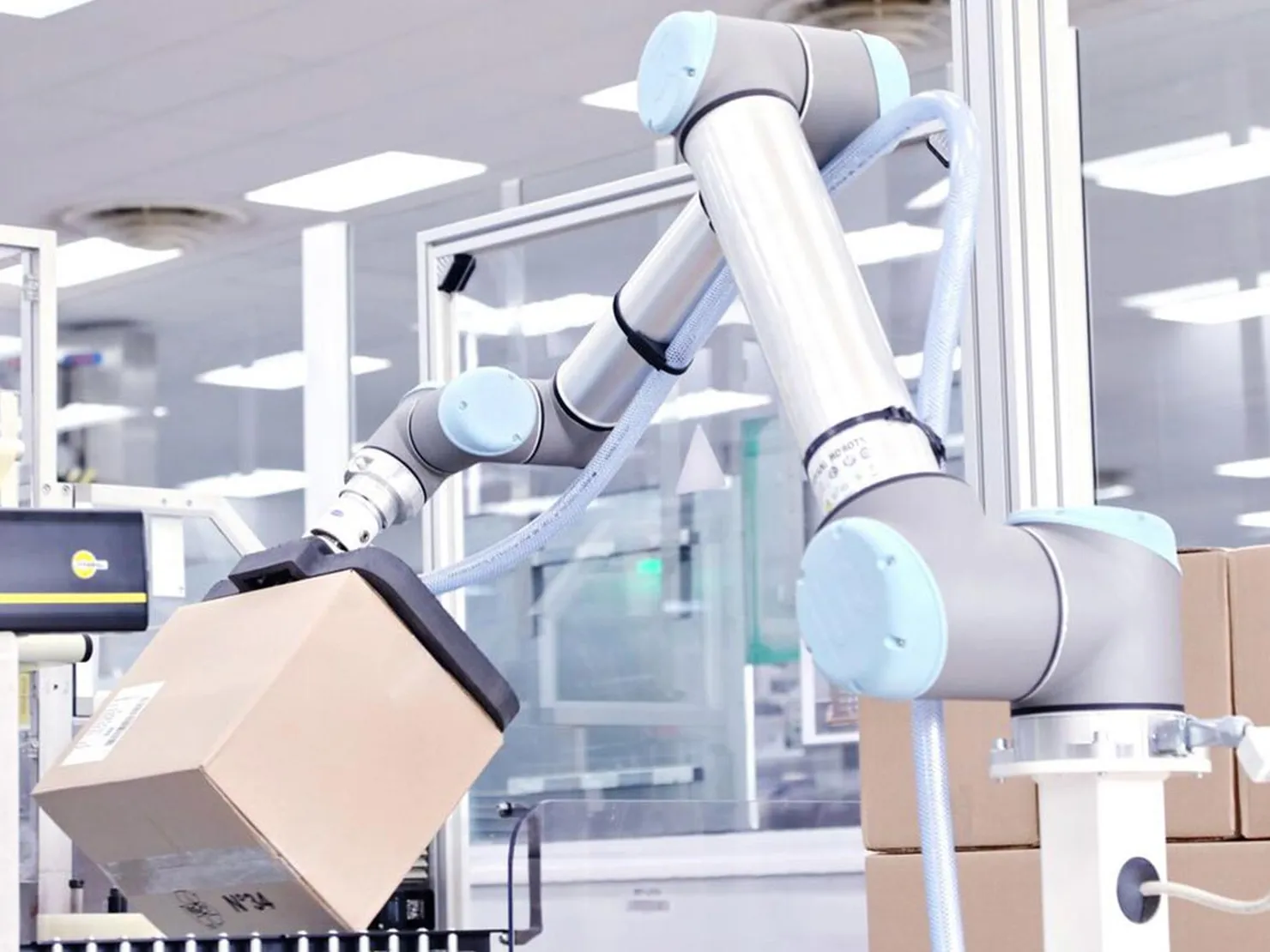

Robotic arms can be used in a very wide variety of ways. Typical areas of application are

- Machine operation

- Palletizing

- Packing

- Bolting

- Mount

- Inspection

- Welding

- Sanding

- Polishing

- Varnishing

- Gluing

What can't a cobot do?

Since cobots can also work without a safety fence, output must be limited to ensure occupational safety. The performance limits for cobots are approx.:

- 25 kg payload (H2515 from Doosan Robotics).

- 1750 mm range (UR20 from Universal Robots).

- 0.01 mm repeatability (CR-4ia by Fanuc).

- 2.2 m/s speed (GoFa from ABB).

This performance is comparable to human abilities. If you need more power, you have to rely on special industrial robots.

What are the benefits of cobots?

The focus of cobots on human-robot collaboration offers significant advantages over conventional industrial robots.

1. Easy operation

The cobot market leader Universal Robots advertises that untrained operators can unpack and set up their robot and write a simple program — in less than an hour!

This is made possible by the “hands-on” approach typical of cobots. While classic industrial robots are initially programmed in simulated environments, cobots can be moved by hand into the desired position. These individual positions then only need to be linked to a movement type to program a process.

The robot therefore does not require a robot-specific programming language, but is simply operated via a touchpad (so-called teach pendant) with an intuitive GUI. Rainbow Robotics' RB series even uses a commercially available Samsung Galaxy tablet for programming!

2. Easy assembly

Cobots are compact power packs. Models like the RB16-900 Rainbow Robotics can lift a payload of 16 kg with a dead weight of just 32 kg. This low dead weight enables floor, ceiling and wall mounting.

It is also possible to mount cobots on mobile robot cabinets or autonomous vehicles. One example of application for this would be machine operation. Before work, the cobot is brought to the machine with a workpiece tray so that it can process a small batch overnight.

3. Can be used flexibly

The enormous variety of accessories for collaborative robots allows them to be used for a wide variety of tasks in a wide variety of environments.

There are end effectors such as

- grippers (with vacuum, magnet, pneumatic, hydraulic or electric)

- process tools (for grinding, polishing, welding, gluing or spraying)

- sensors (such as laser, ultrasound, infrared, or camera systems)

Other accessories include

- linear axes (allow the robot to move along a linear axis)

- robotic cabinets

- robotic protective covers

- cable routings

- And much more

Some cobot models are also designed for specific environments. Die RB-N series by Rainbow Robotics, for example, was developed for the food and beverage industry and is therefore NSF certified.

4. Quick ROI

Because cobots are able to to automate previously unthinkable processes and significantly reduce complexity, amortization within 4 to 15 months is common in industry.

A final advantage that results from the above properties is the quick repurpose. Should process requirements change in the future, a relatively cost-effective conversion can be responded to — so that the cobot can continue to be used.

Which cobot manufacturers are there?

Relevant cobot manufacturers on the EU market are

- Universal Robots

- Rainbow Robotics

- Doosan Robotics

- ABB

- KUKA

- Fanuc

- Kassow Robots

- Franka Emika

- Agile Robots

An overview of the most important cobots with technical data and prices can be found here.

How much does a cobot cost?

Die decisive factors for prices of a cobot are

- the required payload

- the required range

- and the producer of the cobot

Example: The product range of the world market leader Universal Robots starts with UR3e with 3 kg payload and 500mm range for approx. 25,000€ And ends at UR20 with 20 kg payload and 1750mm range for approx. 50,000€.

Universal Robots benefits from a large ecosystem of training material, standard solutions, integrators and certified robot accessories.

To save costs, you can also switch to lesser-known robot manufacturers. This is how the product range of newcomer Rainbow Robotics starts at approx. 17,000€ with a payload of 3 kg and a range of 730 mm.

Overall, cobots therefore cost between 20,000 and 50,000€ .

How much does cobot automation cost?

The prices of cobots are easy to research. But that doesn't answer the actual question: What does the entire automation cost?

The total costs of automation can be divided into

- the purchase costs for the robots

- Costs for End effectors and peripherals

- services for development and installation.

Briefly about the definition:

- End effectors: Are they Tools at the end of the robot arm

- Peripherals are products in the immediate area of the robot system, such as protective covers, bases or sensors. The end effector is therefore also a peripheral element.

It is very difficult to estimate the costs of the periphery in general, as the variety is incredibly wide. Experience has shown, however, that they often around a third of the total costs out of automation.

The costs of services also vary greatly — also depending on how much the company must/can buy or provide itself. The following services are usually required

- Mechanical & electrical design

- Assembly and installation

- Programming (robot & controller)

- Preparation of CE documentation

- Maintenance and Support

- Employee training

The costs for all services are usually also at a third of the total costs.

As a rule of thumb, you can roughly estimate that the total costs are divided into three thirds:

- 1/3 for the cobot

- 1/3 for the periphery

- 1/3 for services

However, this only applies to more complex processes involving human-robot collaboration.

CE documentation and programming is much easier (and therefore less expensive) if the work area is protected by a light barrier, for example, and the robot simply stops when someone enters the work area.

Sometimes there are standard solutions for applications such as palletizing (e.g. from Robotiq) and CNC machine automation (e.g. from Robojob). If these fit into the environment, further costs can be saved by using standard components that have already been developed.

Help with further questions

We are happy to answer any questions you may have about automation. We are a collaborative robotics system integrator with over 30 years experience. Just get in touch and talk to our robotics experts to see if we can help you!