A robotic solution for automated surface treatment

Highest surface quality around the clock and even with complex shapes — this is what our robot automation makes possible. Relieve your employees and talk to one of our robotics experts today about the costs and feasibility for your processes.

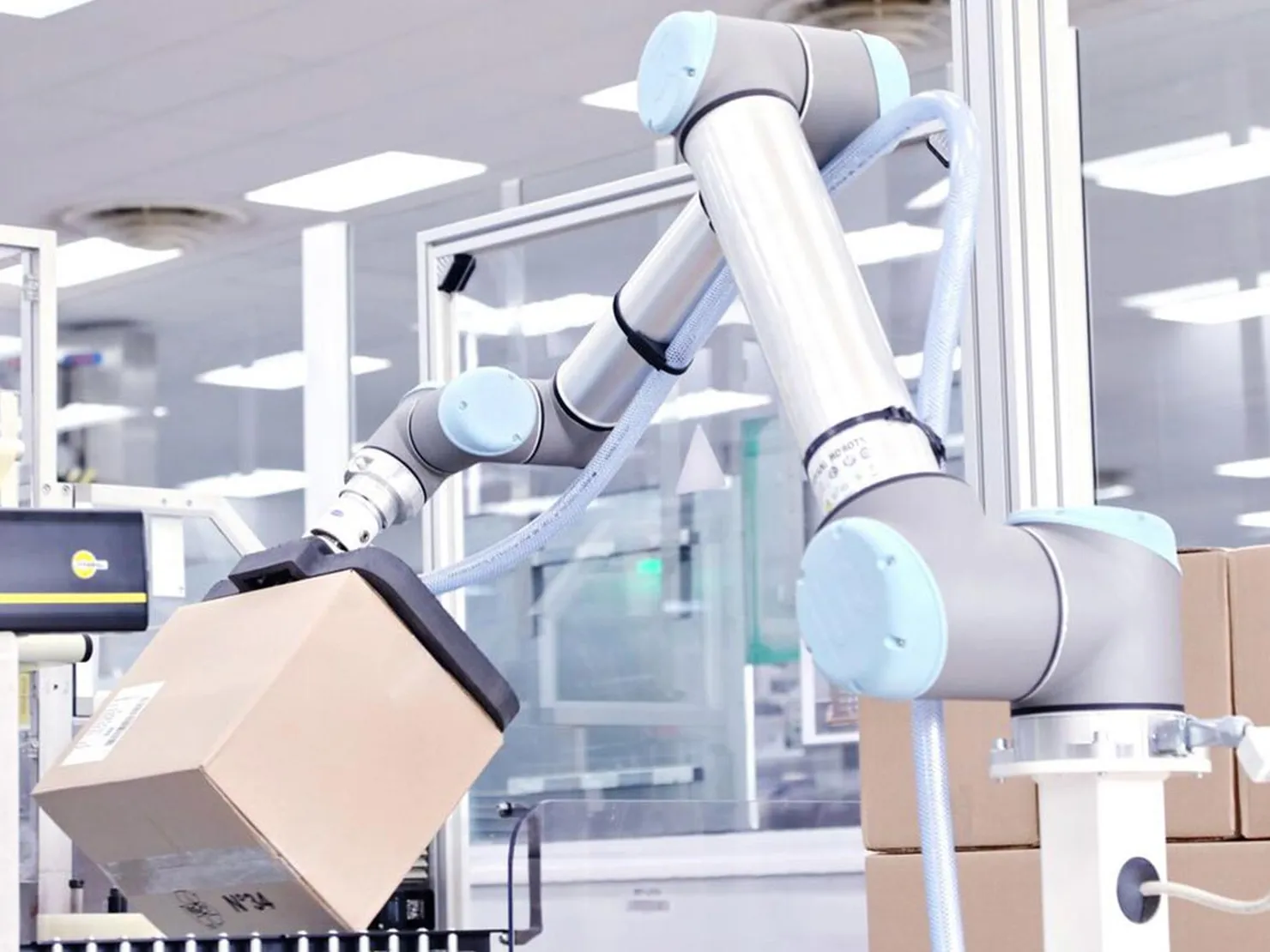

Surface treatment: an ideal application for sensitive robots

Collaborative robots (cobots) are ideal for grinding, polishing or deburring due to the integrated force control. Thanks to integrated collision detection, cobots can share the work space with humans even without a protective cage, which enables efficient collaboration in confined spaces. In addition, cobots are extremely user-friendly, meaning that even employees without programming knowledge can quickly set up new forms via the intuitive graphical user interface.

Highest quality around the clock thanks to constant contact force

Sophisticated end-of-arm tooling enables a defined contact force with interactive compensation of surface tolerances of up to 100 mm, i.e. consistent quality around the clock. The application allows the processing of a wide variety of surfaces, whether steel, aluminum, titanium, magnesium, carbon, plastic, wood or ceramic. With the 6-axis robot, even complex shapes can be sanded precisely.

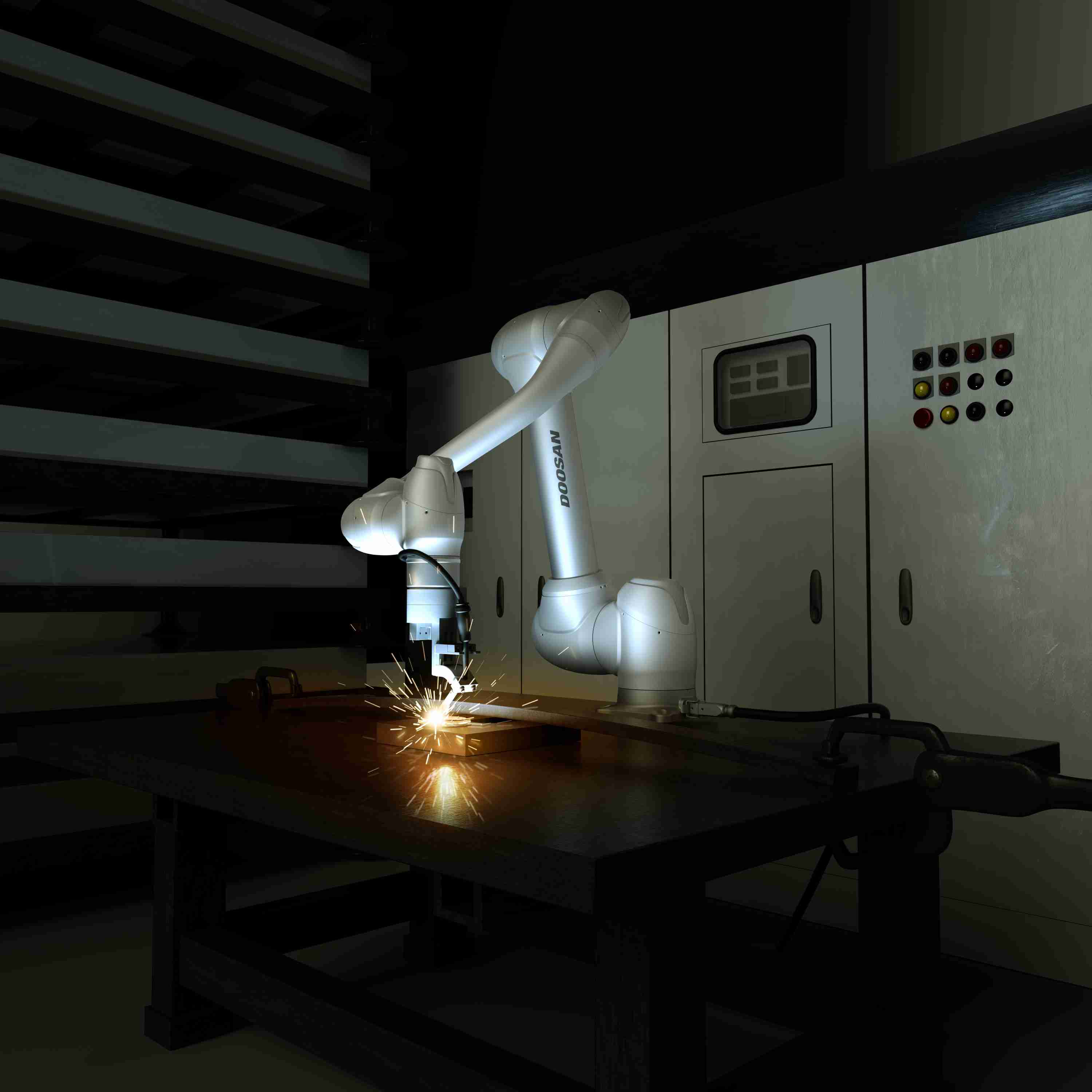

An example with Doosan Robotics

A short video of a Doosan Robotics Cobot, which is on a Doosan Mobile Base when polishing a complex shape with constant contact force generated by the ACF (Active Contact Flange) of Ferrobotics.

Your benefits at a glance

A wide variety of surfaces

Whether steel, aluminum, titanium, magnesium, carbon, plastic, wood or ceramic — the robot can process all surfaces with appropriate end effectors.

Complex shapes

An agile 6-axis robot enables a wide variety of shapes to be treated precisely.

A wide range of processes

Whether sanding, polishing, cleaning, laminating, stripping, brushing, deburring, ironing — the robot can automate all processes with appropriate end effectors

Collaborative

Thanks to integrated collision detection, the robot can work closely with humans even without a protective cage.

Space-saving

The robot weighs only around 40 kg, has a very small footprint and no bulky protective cage, which saves valuable space.

CE documentation

Each of our robotic solutions comes with detailed risk assessment and CE documentation to ensure a safe working environment.

Easy operation

Thanks to the intuitive graphical user interface, even employees without programming knowledge can quickly set up new processes.

Mobile base

Installing the robot on a mobile base makes the application even more flexible.

Flexible

The ease of use of the application also enables rapid adaptation to new processes should requirements change in the future.

The next steps to your robotic solution

In just five steps and a few weeks, we will guide you to your individual automation.

A short initial conversation to get to know each other, define the requirements, estimate feasibility and costs.

Once we have discussed your solution and a collaboration appears useful, we will arrange a non-binding appointment with you on site. We visit your production, check the conditions and create a final concept.

As soon as the concept is ready, we will prepare a binding offer. We are also happy to prepare a profitability calculation.

We build the plant according to your requirements in our production. Depending on the project, this usually takes 4 to 8 weeks.

We deliver the system (as far as possible) on a turnkey basis to minimize downtime. You can then use the power of the robotic solution around the clock!

Let's automate effectively together

We are a system integrator with more than 30 years of experience in automation technology. Benefit from our know-how from hundreds of projects and make your automation a success faster!